Biogas harnessing from POME is considered as part and parcel of the 3Ps involved in sustainability

i.e. planet, people and profit, to be benefited by the oil palm industry as a whole.

Generally, biogas harnessing can take care of the 3Ps which cover the following:

• Planet - reduce global and local environmental impact (due to reduction of greenhouse gas

(GHG) emissions i.e. methane and CO2); reduce dependence on fossil fuel, and enhances fuel

diversity and security of energy supply in line with the government’s strategy to implement

renewable energy;

• People - promote sustainable development in palm oil milling process as part of the processes

for the whole palm oil value chain;

• Profit - enhance revenue in palm oil milling process (carbon credits, saving in biomass used

for power generation etc.):

Other benefits (specifically for biogas project includes:

• Reduce land use for POME treatment;

• Reduce tax from the government;

• Enhance revenue for palm oil mill;

• Generate business for the biomass supply chain and local technology collaborators;

• Encourage technology innovation in green technologies in line with the government policy

and planning– increased reputable image of palm oil mill;

• Non-polluted beautiful working environment surrounding the mill;

• Saving of energy for internal consumption;

• Income from electricity generation;

• Produce organic fertilizer for land irrigation;

• Gain of carbon credits.

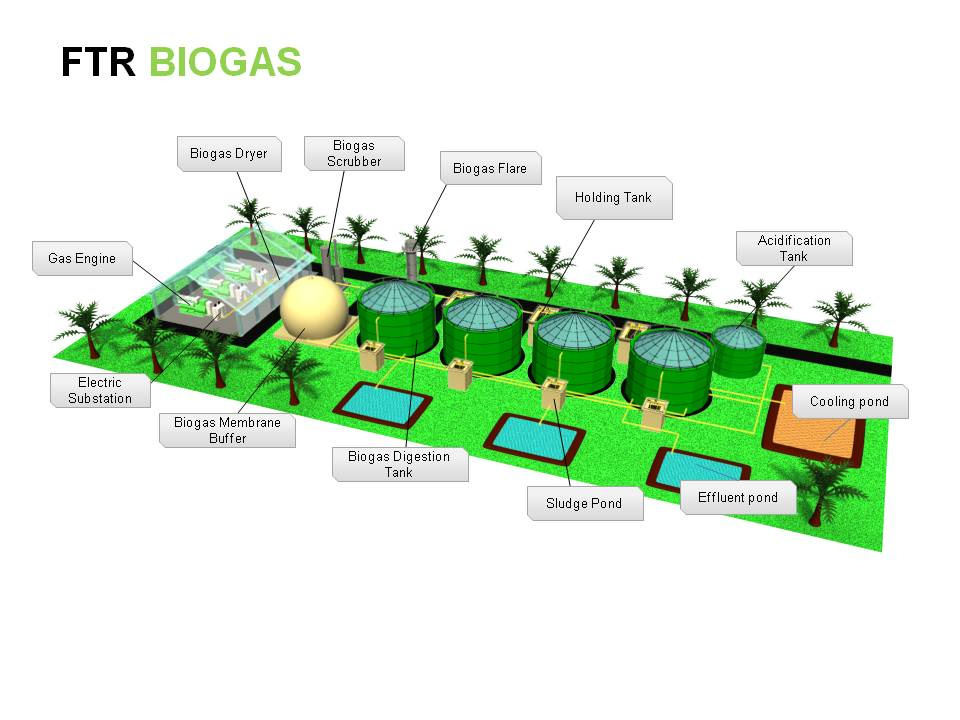

BRIEF INTRODUCTION FOR FTR BIO GAS SYSTEM

The difference in Fast Track Resources methane fermentation technology compared to other

technologies is in its design – in controlling the effluent’s flow and allowing microorganisms to

ferment in an undisturbed environment with maximum biological activities.

1. Our Methane Fermentation System using Advanced technology of USR (up-flow solids

reactor) and has the following advantages:

a. High COD loading factor: 6 - 8 kg COD/m³.d

b. HRT < SRT & MRT, Smaller system, lower construction cost

c. COD, BOD removal rate: 90 - 95%. High organics removal rate implies good economic

returns and methane production higher than other system.

d. No mixer in digester tanks, save energy and low O&M cost, easy to manage

e. Good materials (Enamel-coating), long service life (more than 30 years) implies easy

management and low operation cost.

f. Double safety device, system safety.

2. Our system have pretreatment system (acidification tank)

In acidification tank, the macromolecular organic matters of POME be hydrolyzed and acidified

under the action of the extracellular enzyme and intracellular enzyme, become the small

molecules that mainly of acetic acid (CH3COOH). Facilitate anaerobe digestion, enhance the

effect of fermentation.

3. Comparison the material of Digester

We use Enamel material to build Acidification tank and Digester, this material is beautiful, long

service life, simple maintenance.

| Mild Steel Tank | Enamel Tank |  |

|

| Life | > 15years | > 30years | |

| Maintenance | Need anti-rust treatment and repaint | No maintenance required | |

| Others | Appearance easy to damage | Modern, beautiful& durable |